OEM development

Your competent partner from development to series production

The development of new automated applications in labs and diagnostic fields are unbelievably dynamic. QInstruments is a committed partner to instrument and device manufacturers around the world. QInstruments OEM partners enjoy access to a community of engineers ready to help get products to market faster. We provide our customers and partners with individual applications or end-to-end solutions that suit their every day need.

Our service

- Design studies

- Development of article designs

- Design of thermal concepts

- Calculation and simulation

- Creation of electronic circuits and programs

- Functional programming

- Customizing and optimizing of applications

- Prototyping

- Series production

- Reliability tests

- CE and IVD approval

References

QInstruments offers contract development as well as manufacturing features to the Life Science industry during the past several years. We have successfully completed a number of instrument development contracts for our partners.

Finally, the results of initial projects were transferred into new products and series production. These products are manufactured exclusively in Germany and comply with our stringent quality and sustainability criteria.

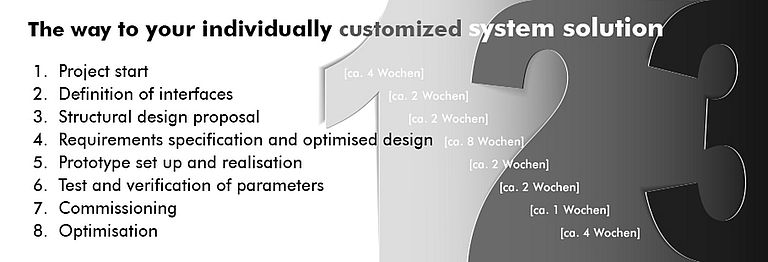

Project plan for individual system solutions

Only very few products from QInstruments are shipped out as standard products. In most cases our products are delivered as customised versions.

The most important parameters and the specifications for our customised solutions are best organised in partnership with our customers.

It is our competence to provide complete customized systems. In case of any questions please contact us, we will be pleased to help.

1. Project start

Duration approximately 4 weeks

Please use our non-binding "Project Start" technical questionnaire to supply us with all the important information about your planned application. This will make it much easier for us to give you our full support in the realisation of your project.

Requirements profile:

• Information about movement sequence

• Environmental conditions (temperature, pressure [vacuum], clean-room requirements)

• Accuracy requirements: repeatability, transmission accuracy, etc.

• Speed requirements: the maximum/minimum available actuation time, output side speed, speed over time, synchronisation

• Torque/actuation force: nominal load, peak load

• Quantities for prototype/series

QInstruments will be happy to provide you with informational material about implemented solutions for similar situations.

2. Definition of interfaces

Duration approximately 2 weeks

• Define system limits and delivery requirements as well as system protection measures against incorrect operation

• Define structural interfaces (type of fixation, drill pattern, mounting surfaces)

• Establish electrical interfaces (cable, connector)

• Other interfaces such as vacuum and liquid connections

3. Structural design proposal

Duration approximately 2 weeks

• Proposed system design

• Design proposal for the various interfaces (mechanical, electrical, media, tools)

• Achievable technical data for design proposal (actuation times, vacuum levels, repeatability accuracy)

• Special measures: e.g. materials, coatings, lubricants, seals

• Proposal for prototypes and series

4. Requirements specification and optimised design

Duration approximately 8 weeks

• Agreement technical specifications and design

• Establishment of technical and economic details

• Order of prototypes

5. Prototype set up and realisation

Duration approximately 2 weeks

• Individual part drawings

• Manufacture/order individual parts

• Assembly of prototypes

• Commissioning

6. Test and verification of parameters

Duration approximately 2 weeks

• Test of parameters specified in the technical specification

• Evaluate maximum achievable parameters

• Create acceptance protocol

7. Commissioning

Duration approximately 1 week

• Delivery of prototypes

• Installation of system by the customer

• Commissioning by the customer

• Customer tests

• Verification of parameters

8. Optimization

Duration approximately 4 weeks

• Accommodate further boundary conditions

• Optimisation of individual parameters

We would be glad to work out a structural design proposal for you at no charge.