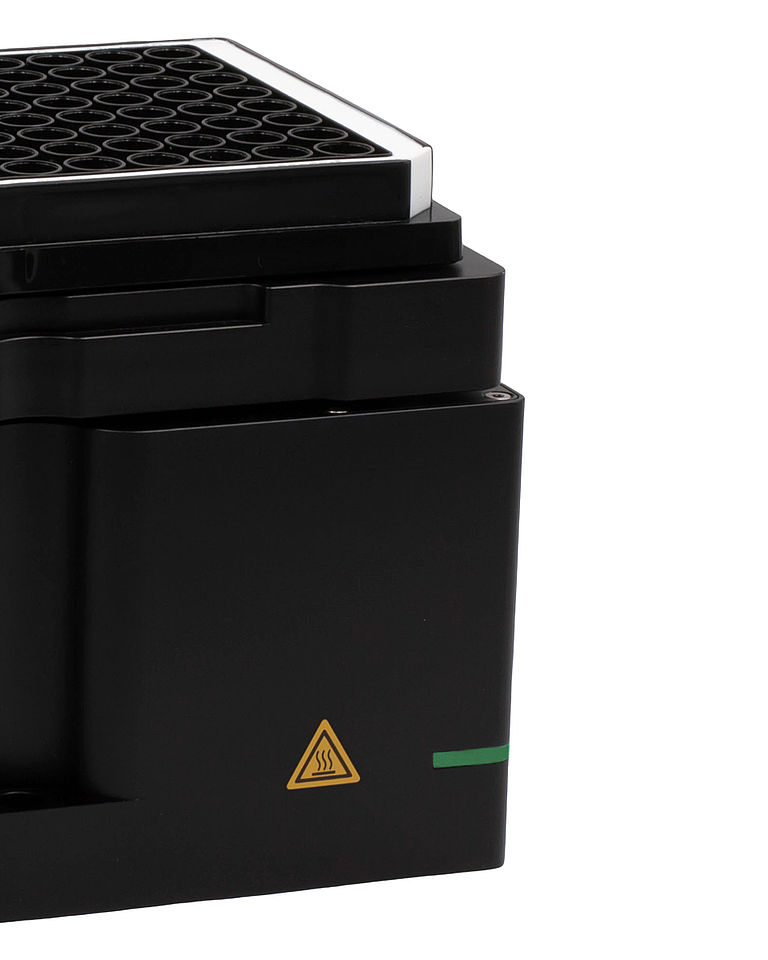

BioShake Q1

Aluminium -20°C - 99.9°C 2 mm orbit 3000 rpm Adapter Deep Well 96/384 Well

Key Benefits

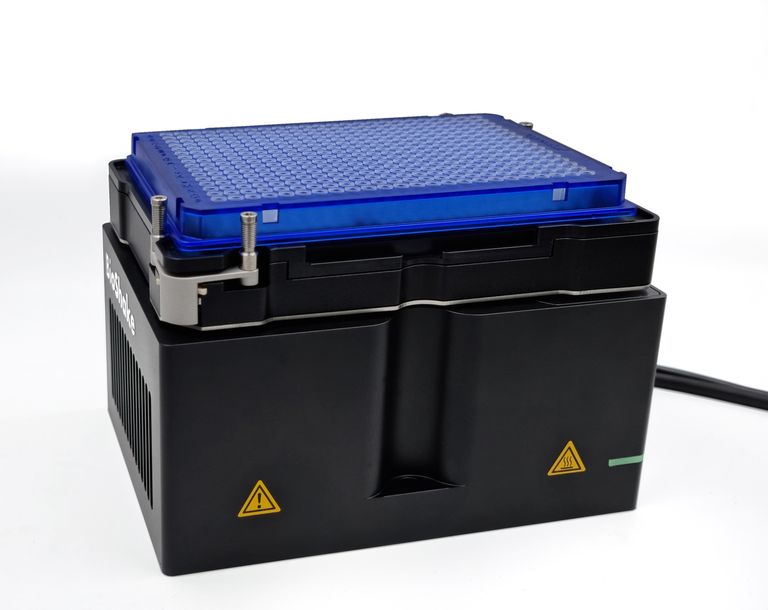

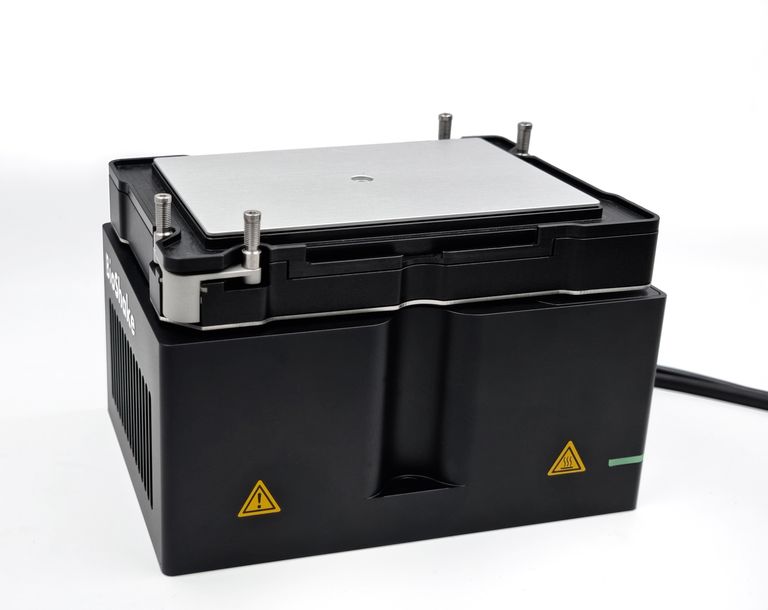

The BioShake Q1 is the ideal and the most effective thermoshaker for 48/96/384 well microplates. The optimized orbital mixing system & mass balance elements reduce noise and vibrations during fully loaded plates' cooling, heating and mixing.

Fully adjustable between -20°C and 99.9°C and well beyond most other brands' cooling & heating accuracies, the Q1 guarantees excellent temperature control for every application.

ELM's patented locking mechanism locks the microplates quickly and safely, even at the highest mixing frequencies. Fast mixing processes with frequent plate changes can be performed in the routine easily and safely.

The Q1 module is only slightly larger than a standard microplate.

All parts are inside the unit; no external components are necessary.

Small. Light. Efficient. Quiet.

- Cooling & Heating & Mixing in one unit

- Fast mixing from 200 up to 3,000 rpm

- Fully adjustable between -20° to 99.9°C

- Temperature range 24 K below RT, max: 99.9 °C

- Cooling/Heating speed 12 K/min above RT

- Wide range of perfected thermo-adapters

- No further external electronics

- Plate locking ELM ± 0.1 mm

- Sensored zero-position ± 0.1 mm

- Stylish aluminium housing

- Reliable Peltier technology without coolant

- Easy installation & simple start-up

- Maintenance-free for many years

- 2 years full warranty

BioShake Q1 from QINSTRUMENTS set the new standard in temperature control and mixing.

ADVANCED TECHNOLOGY

Save time.

Combining the mixing operation with the incubation phase reduces reaction process times and operator workload, and the efficiency of many procedures increases, resulting in higher throughput.

The first-class finished aluminium housing gives BioShake Q1 its essential functionality. It provides high security and device stability and ensures a long service life.

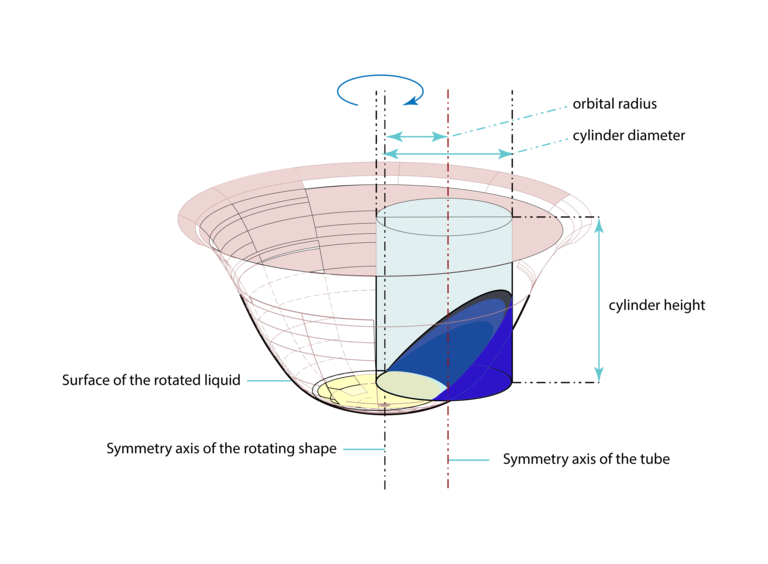

GENTLE MIXING OF SAMPLES

By planar orbital motion

German-designed and manufactured BioShake Q1 thermoshaker offers an ultra-efficient, 2-dimensional shaking axis so that samples mix completely in a fraction of the time of competing systems. The mixing orbit of 2.0 mm is always constant. The orbital shaking is precisely controlled; you need never spin down your plates after mixing.

Fully adjustable between 200 and 3,000 rpm, well beyond the speeds of most other brands, it guarantees fast, splatter-free mixing for tubes, glass vials or across an entire 96-well microplate.

HOMOGENEOUS COOLING & HEATING

Using powerful Peltier element technology

Many lab experiments require fast heating and cooling steps in a very accurate manner in the range of -20°C up to 99°C. Precise temperature control is achieved for Q1 using optimally balanced cooling and heating elements. The novel Peltier technology, combined with minimized electronics and reliable algorithms, ensures a long, useful life in each lab automation project.

BioShake Q1 is the ideal device to set and maintain temperatures accurately. The module is only slightly larger than a standard microplate. Fully adjustable between -20°C and 99°C and well beyond most other brands' cooling & heating accuracies, Q1 guarantees excellent temperature control for microplates, tubes and vials.

All parts inside, only a PC is needed for control.

Temperatures are selectable from -20°C to 99°C in steps of 0.1°C. The nominal regulation accuracy is better than ±0.2°C with uniformity of temperature distribution better than ±1.0°C at 4°C across the cooling surface.

Exchangeable thermo-adapters and thermal blocks perfectly adapt to microplates, tubes or glass vials.

PATENTED EDGE LOCKING MECHANISM

Suitable for all microplates

Many robotic applications require precise dimensional spacing of pipet tips and robotic grippers relative to a microplate. The Edge Locking Mechanism (ELM) is the complete answer for repeatable and accurate positioning of microplates on an automated deck. It consists of 2x2 stainless steel pins and a 2-point electromechanical mechanism to lock down microplates in the module's centre safely.

This patented locking mechanism locks the microplates quickly and safely, even at the highest mixing frequencies. Fast mixing processes with frequent plate changes can be performed in the routine easily and safely.

For the gripping of microplates, the ELM opens the clamping automatically. This "universal" design is perfect for all types of plates in SBS format 127.7 x 85.5 mm: from low profile to deep-well; from 96- to 1536-well. And when "locked" into place, the microplate varies by as little as +/- 0.1 mm, making demanding manipulations a breeze.

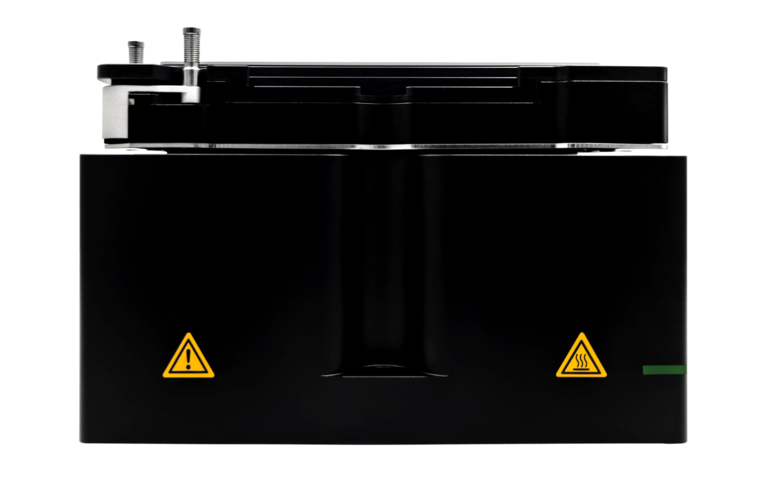

LED INDICATION LIGHT

Simple status monitoring

All BioShake devices have advanced internal algorithms and sensors for monitoring operating parameters and error detection. Any errors are sent out via the RS232 communication interface. Those are easier to detect and localize.

All BioShake automation devices are equipped with one integrated LED indication light in front to improve the functional testing during installation and visualize the operating status. The indication light allows a quick function test and error control. The green or red status lights up or is disabled. In case of failure, the error list should be read out via the RS232 command to help detect the error more precisely.

ZERO POSITION

Locked & sensor-controlled zero-positioning

In time-adjustable stopping operations, a defined zero position is automatically extended and locked with an accuracy of 0.1 mm.

An integrated sensor monitors this zero position and its accuracy. This functionality ensures and simplifies the loading and removal processes and allows accurate pipetting.

EXCHANGABLE THERMO ADAPTERS

For a wide range of applications

The BioShake Q1 comes with various standardized and specific thermo-adapter plates. The replacement of the adapters is very simple.

Perfect-shaped adapters allow an optimal fit for standard tubes, lysis tubes, microplates, glass vials and other sample vessels. Excellent temperature uniformity and homogeneity guarantee reliable results for all samples.

COMFORT

Simple, intuitive integration in robots and programming

The BioShake operates via RS232 or USB user interface. An automatic initialization will start after turn on.

A simple command set allows you to control hardware and sensors easily. The process parameters are constantly managed and read out. After turning it off, a self-setting zero position of the shaker plate makes the time-consuming electrical tracking unnecessary. This functionality ensures maximum operating security also in the unmonitored continuous operation.

QINSTRUMENTS provides approved SILA® drivers for all BioShake units.

UNIQUE DESIGN MEETS HIGH-END TECHNOLOGY

First-class finished aluminium housing

The unique, efficient design and the most compact housing result in beautiful, well-defined laboratory equipment. Therefore, the first-class finished aluminium housing gives BioShake Q1 its essential functionality. It provides high security and device stability and ensures a long service life.

The safety of the user and ease of use is a priority.

MADE IN GERMANY

High-end instruments for daily routine

A perfectly harmonious blend of high-tech and handmade. "Made in Germany" has always been a recipe for success for QInstruments. 100% of QInstruments production takes place in Germany.

The focus is on human diligence and on being environmentally friendly. The company upholds its quality guarantee through consistent quality management. For more than 20 years, these lab automation professionals from Jena have used only high-quality materials to ensure sustainable production, applied innovative thinking and undertaken research in a future-oriented way – all as a matter of course.

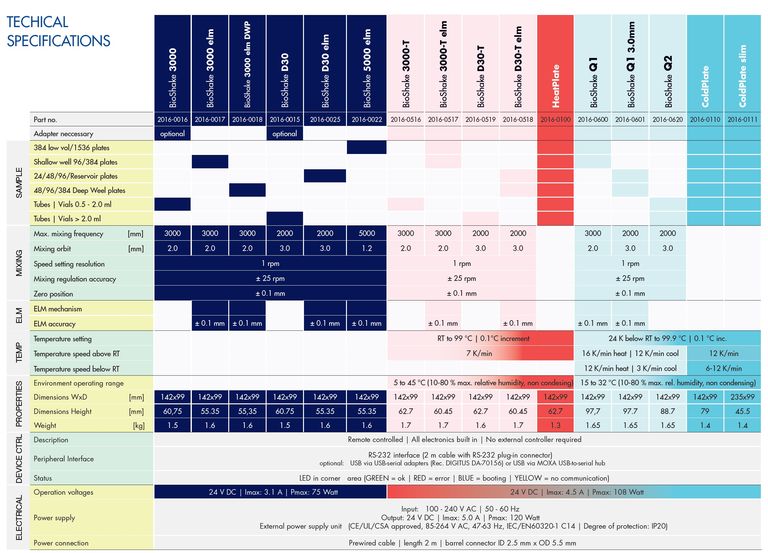

Lab Automation | Product selection guide

MICROPLATES

Recommended mixing speeds

* Values for 96 - 384 well plates refer to diluted fluids and mixing orbit of 2.0 mm.

** Values for 1536 well plates refer to mixing orbit of 1.2 mm.

| Filling volume in % | 96 well plates* | 384 well plates* | 384 well plates* | 1536 well plates** |

|---|---|---|---|---|

10 % | 1800 - 2200 rpm | 2200 - 2600 rpm | 2800 - 3000 rpm | 4000 - 5000 rpm |

25 % | 1600 - 2000 rpm | 2000 - 2400 rpm | 2400 - 3000 rpm | 3500 - 4500 rpm |

50 % | 1400 - 1800 rpm | 1800 - 2200 rpm | 2200 - 2600 rpm | 2800 - 3500 rpm |

75 % | 1200 - 1600 rpm | 1600 - 2000 rpm | 2000 - 2400 rpm | 2500 - 3000 rpm |

TUBES

Recommended mixing speeds

All values refer to diluted fluids and mixing orbit of 2.0 mm.

| Filling volume in % | 0.2 ml tubes | 0.5 ml tubes | 1.5 ml tubes | 2.0 ml tubes |

|---|---|---|---|---|

10-50 % | 1400 - 1800 rpm | 1200 - 1600 rpm | 1000 - 1300 rpm | 1000 - 1300 rpm |

50-75 % | 1200 - 1500 rpm | 1100 - 1300 rpm | 1000 - 1200 rpm | 900 - 1200 rpm |

75-90 % | 1000 - 1300 rpm | 1000 - 1200 rpm | 900 - 1100 rpm | 900 - 1100 rpm |

GLASS VIALS

Recommended mixing speeds

All values refer to diluted fluids and mixing orbit of 2.0 mm.

| Filling volume in % | 0.5 ml vials | 2.0 ml vials | 4.0 ml vials | 6.0 ml vials |

|---|---|---|---|---|

10-50 % | 1400 - 1800 rpm | 1200 - 1600 rpm | 1000 - 1300 rpm | 1000 - 1300 rpm |

50-75 % | 1200 - 1500 rpm | 1100 - 1300 rpm | 1000 - 1200 rpm | 900 - 1200 rpm |

75-90 % | 1000 - 1300 rpm | 1000 - 1200 rpm | 900 - 1100 rpm | 900 - 1100 rpm |

For microplates use only | |

|---|---|

| Microplates | All microplates according SBS format 48-, 96- up to 384- well microplates, deep well plates, PCR plates (e.g Eppendorf®, Brandt®, Nunc®, Greiner Bio-One®) |

Supported microplate flange heights | 2.5 mm, 4.0 mm and 6.1 mm |

Mixing | |

| Mixing frequency | 200 to 3,000 rpm (Maximum allowed mixing speed depends on the value and type of load. We recommend to test the mixing speed you want to use with a microtiter plate and water to check if liquid might get spilled and correct clamping is ensured.) |

| Mixing orbit | constant 2.0 mm diameter (other orbit diameter 1.2 / 3.0 mm on request) |

| Speed setting resolution | 1 rpm (linear increments) |

| Mixing regulation accuracy | ± 25 rpm |

| Zero position | Locked zero position, adjustable within 1-4 sec, accuracy ± 0.1 mm |

| Zero position accuracy | ± 0.1 mm |

Temperature | |

| Temperature range | Adjustable from -20°C to 99.9°C Up to 24 Kelvin under room temperature, depends on thermo adapter Typical range +4°C to 99.9°C (conditions: RT = 21°C, Adapter: 2016-1041, 96-well PCR, adapter temperature) |

| Temperature setting | 0.1°C increment |

| Temperature sensor resolution | 0.008°C |

| Temperature sensor accuracy | ± 0.2°C (maximum) from -10°C to +85°C ± 0.25°C (maximum) from -20°C to +100°C |

Temperature uniformity | ± 1.0 K at 4°C ± 0.5 K at 15°C ± 0.5 K at 40°C ± 1.0 K at 90°C (conditions: RT = 21°C, Adapter: 2016-1041, 96-well PCR, adapter temperature) |

| Cooling/Heating speed above RT | ca. 16 K/min Heating → 5.0 min from 25°C to 95°C ca. 12 K/min Cooling → 6.5 min from 95°C to 25°C (conditions: RT = 21°C, Adapter: 2016-1041, 96-well PCR, adapter temperature) |

| Cooling/Heating speed below RT | ca. 12 K/min Heating → 2.2 min from 4°C to 25°C ca. 3 K/min Cooling → 7.0 min from 25°C to 4°C (conditions: RT = 21°C, Adapter: 2016-1041, 96-well PCR, adapter temperature) |

Plate locking ELM | |

| ELM open modus | Plate locking open, ready for free handling with robot gripper |

| ELM closed modus | Plate locking closed, strong diagonal centered fi xation, locked position with accuracy ± 0.1 mm |

ELM Position Accuracy | ± 0.1 mm |

Device control | |

Electronic control board | Completely accommodated in the smallest housing |

Controller | Micro controller (32-Bit-ARM-Cortex-M4-Prozessor) |

Operation control | Remote controlled |

User interface | EIA-232 / RS-232 interface (2m cable with RS-232 plug-in connector) USB via DIGITUS DA-70156 USB-Serial Adapters USB via MOXA USB-to-Serial Hub |

| Status & alarm | LED in corner area GREEN = ok | RED = alarm | BLUE = booting | yellow = no communication |

Electrical | |

| Operating Voltages | 24 VDC input . Imax: 4.5 A . Peff: 85 Watt . Pmax: 108 Watt |

| External power supply | External power supply unit (CE/UL/CSA approved, 85-264 VAC, 47-63 Hz, 120W, IEC/EN60320-1 C14) Only use the device with the delivered power supply or one that meets the given specifications. |

| Power cord | Only use the device with the delivered power cord. If another power cord is used ensure the wire diameter is adequate for the power supply. |

| 24 V DC connection | Prewired cable, length 2 m, barrel connector ID 2.5 x OD 5.5 mm |

| RS-232 interface | Prewired cable, length 2 m, with RS-232 plug-in connector |

Properties | |

| Housing Material | Aluminum anodized, black |

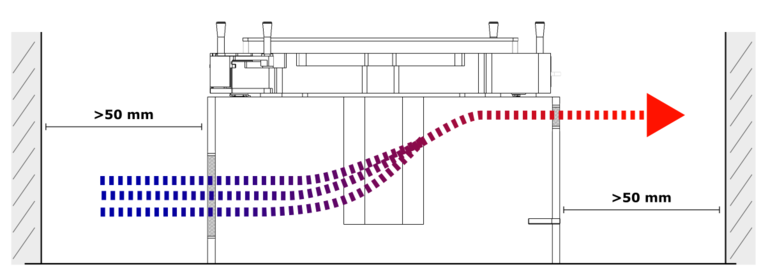

| Environment operating range | +15°C to 32°C 10-80 % max. relative humidity (non condensing) 0-2000 m above sea level Condensate can prevent the Shaking devices from operating properly and can damage the BioShake Q1. Condensate should be eliminated on a daily basis or more otfen, for example by heating cycles in between cooling cycles. |

| Degree of protection | IP20 Protected against solid objects up to 12 mm No protection against water |

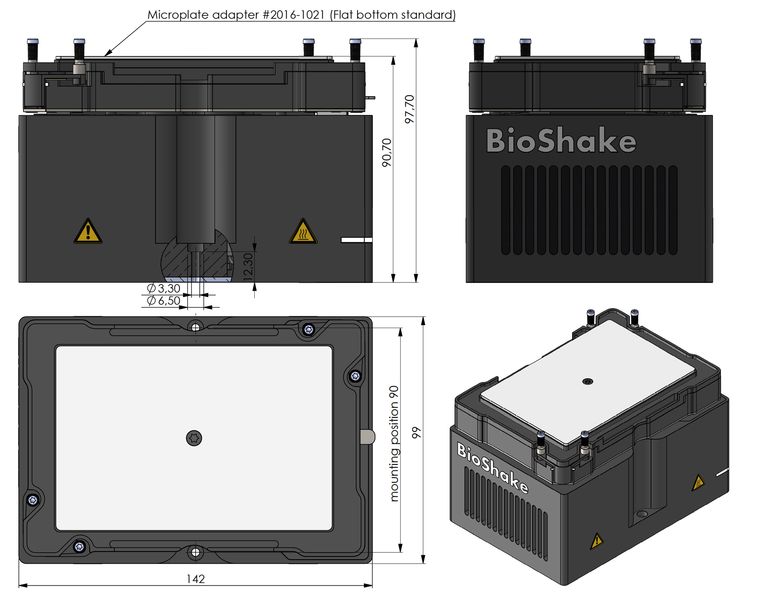

| Dimensions (W x D x H) | 142 x 99 x 97.7 mm → 5.59 x 3.897 x 3.846 inch (top edge of ELM pins) |

| Weight | 1.65 kg (3.637 lbs) netto |

Details

Dimensions

Airflow

Here we present an overview of available standard adapters, compatible with all automation units:

BioShake 3000 | BioShake 3000-T | BioShake 3000-T elm | BioShake D30-T elm | BioShake Q1 | HeatPlate | ColdPlate

Microplates

Standard

2016-1021 | Microplate . Flat bottom standard

2016-1022 | Microplate . Flat bottom High Base

2016-1032 | Microplate . 96 well round bottom

PCR microplates

2016-1041 | PCR plate . Eppendorf® 96/150µl

2016-1042 | PCR plate . Bio-Rad® 96/150µl

2016-1051 | PCR plate . Eppendorf® 384/40µl

Deep well & storage plates

2016-1121 | Deep well . Eppendorf® 96/500-1000 µl

2016-1141 | Deep well . BRAND®/Trefflabs® 96/1.1 ml

2016-1151 | Deep well . NUNC®/Axygen® 96/2.0 ml

2016-1161 | Deep Well . Axygen® 96/0.6 ml

2016-1171 | Deep Well . Abgene® 96/2.2 ml

2016-1172 | Deep Well . Abgene®/HJ-Bio®/Greiner® 96/0.8-1.2 ml

2016-1181 | Deep Well . Sarstedt® 96/2.2 ml Megablock

2016-1201 | 96 well V bottom . Corning® 96/320 µl

2016-1214 | Deep well . Axygen®/Corning®/StarLab® 96/2.0 ml

2016-1215 | 24 well . Whatman® Uniplate

2016-1217 | Storage plate . NUNC® 96/450 µl

2016-1218 | Deep well . Apricot® 96/2.2 ml

Tubes & Stripes & Vials

Conical shape

2016-1060 | Tubes . 15x 5.0 ml

2016-1061 | Tubes . 24x 2.0 ml . 15x 0.5 ml

2016-1062 | Tubes . 24x 1.5 ml . 15x 0.5 ml

2016-1063 | Tubes . 40x 0.5 ml . 28x 0.2 ml

2016-1064 | PCR Tubes/Stripes/Plates . 96x 0.25 ml

2016-1093 | FALCON® tubes . 5x 50 ml

2016-1094 | FALCON® Tubes . 12x 15 ml

Cylindrical shape

2016-1069 | Vials . 35x 2.0 ml Ø 10.8 mm

2016-1071 | Vials . 35x 2.0 ml Ø 12 mm

2016-1080 | Vials . 35x 2.0 ml Ø 12.5 mm

2016-1078 | Vials . 24x 2.0 ml Ø 12.7 mm

2016-1081 | Vials . 30x 2.0 ml Ø 13 mm

2016-1072 | Vials . 24x 4.0 ml Ø 15 mm

2016-1073 | Vials . 20x 4.0 ml Ø 17 mm

2016-1074 | Vials . 20x 6.0 ml Ø 19 mm

Technical data sheet

Test software

QCOM 2 is a small test software with a graphical user interface (GUI) to control lab automation instruments from QInstruments, eg. BioShake, ColdPlate, HeatPlate. The main purpose of QCOM 2 is to get easy access to the unit to execute initial testing.

SILA 2 compliant driver

SiLA® is the global initiative to standardize software interfaces in the field of life science research instrumentation. Instigated by the pharmaceutical industry′s need for flexible laboratory automation, the initiative is supported by major device and software suppliers worldwide.

The SiLA® consortium for Standardization in Lab Automation develops and introduces new interface and data management standards allowing rapid integration of lab automation systems. SiLA is a not-for-profit membership corporation with a global footprint and is open to institutions, corporations and individuals active in the life science lab automation industry. Leading system manufacturers, software suppliers, system integrators and Pharma/Biotech corporations have joined the SiLA® consortium and contribute in different technical work groups with their highly skilled experts.

QInstruments provides approved SILA® driver 1 for all BioShake units.

For development of SILA compliant software we work in close cooperation with Equicon.

To obtain help for installing and running the driver, please contact us.

3D CAD models

Certificates / Declarations

Knowledge

Leveraging its foundation in innovative automated solutions, QINSTRUMENTS is a leader in precision mixing and temperature control for sample preparation. QINSTRUMENTS' application-specific solutions, small instruments and OEM modules are used in industries ranging from flow cytometry and forensic chemistry to next-generation sequencing.

QINSTRUMENTS offers extremely robust and quiet orbital shakers, thermoshakers, heating and cooling units for laboratory automation. The black colored premium line is designed for demanding automation processes and defines the global standard for reliable mixing.

No other external components are needed as the electronics are integrated into the smart modules. They are fully equipped for hands-free operation with a comprehensive remote command set for easy software integration.