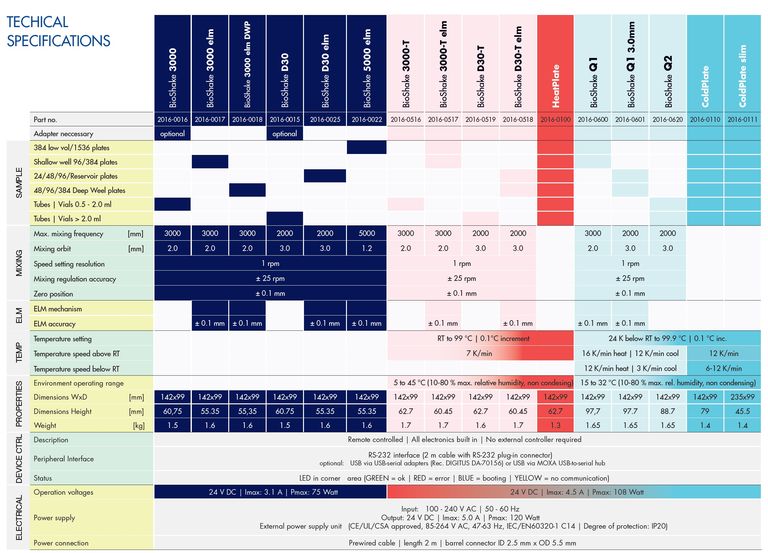

BioShake 3000-T

Aluminium RT - 99°C 2 mm orbit 3000 rpm Adapter Tubes Vials

Key Benefits

The BioShake 3000-T is designed for reliable mixing of vials and tubes. The BioShake 3000-T heats from ambient up to 99 °C in a short time, provides ease of use features, amazing comfort and maximum safety.

Exchangeable adapter plates and thermal blocks enable a perfect adaptation to tubes or glass vials.

BioShake 3000-T delivers outstanding thermal heating performance.

Small. Light. Efficient. Quiet.

- Ideal for vials and tubes

- High-precision heating from ambient to 99°C

- Perfected thermo adapters

- Fast mixing from 200 up to 3,000 rpm

- 2.0 mm mixing orbit

- Sensored zero-position

- All parts indside

- Easy installation & simple start-up

- Stylish aluminium housing

ADVANCED TECHNOLOGY

Save time.

By combining the mixing operation with the incubation phase, reaction process times and operator workload are reduced and efficiency of many procedures is increased, resulting in a higher throughput.

The first-class finished aluminium housing gives the BioShake 3000-T its essential functionality. It provides a high amount of security, device stability and ensures a long service life.

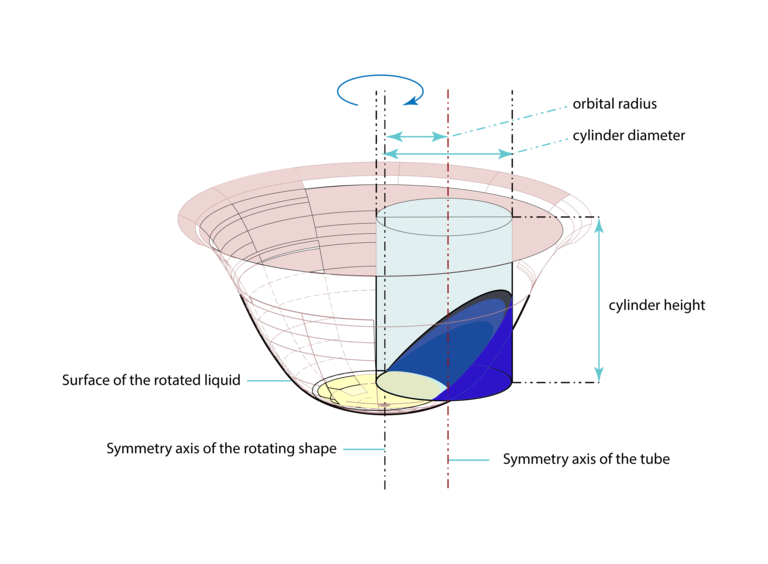

GENTLE MIXING OF SAMPLES

By planar orbital motion

German designed and manufactured, BioShake 3000-T thermoshaker offer an ultra-efficient, 2-dimensional shaking axis so that samples mix completely in a fraction of the time of competing systems. The mixing orbit of 2.0 mm is always constant. The orbital shaking is precisely controlled, in fact, that you need never spin down your plates after mixing.

Fully adjustable between 200 and 3,000 rpm, well beyond the speeds of most other brands, guarantees fast, splatter-free, mixing for tubes, glass vials or across an entire 384-well microplate.

HOMOGENEOUS HEATING

Using large-area heating source in combination with digital sensor electronic

The BioShake 3000-T heats from ambient to 99°C in a short time, provides ease of use features, amazing comfort and maximum safety.

Within the BioShake D30-T elm thinnest large-area heating elements and sensors are integrated. During the heat up time the special electronic control system guarantees the same temperature for all vessels with minimal deviations.

Temperatures are selectable from ambient temperature to 99°C in steps of 1.0°C. The nominal regulation accuracy is better than ±0.1°C with a uniformity of temperature distribution better than ±0.5°C at 45°C across the heating surface.

Exchangeable thermo adapter plates and thermal blocks enable a perfect adaptation to microplates, tubes or glass vials.

LED INDICATION LIGHT

Simple status monotoring

All BioShake devices have advanced internal algorithms and sensors for monitoring operating parameters and error detection. Any errors are sending out via RS232 communication interface. Those are easier to detect and localize.

To improve the functional testing during installation and visualizing the operating status all BioShake automation devices are equipped with one integrated LED indication light in front. The indication light allow a quick function test and error control. This have a green and red status that light up either, or are disabled. In case of failure, the error list should read out via RS232 command, to help detect the error more precisely.

ZERO POSITION

Locked & sensor-controlled zero-positioning

In time adjustable stopping operations a defined zero position is automatically extended and locked with an accuracy of 0.1 mm.

An integrated sensor monitors this zero position and its accuracy. This ensures and simplifies the loading and removal processes and allows accurate pipetting.

EXCHANGABLE THERMO ADAPTERS

For a wide range of applications

The BioShake 3000-T comes with a variety of standardized and specific thermo adapter plates. The replacement of the adapters is very simple.

Perfect shaped adapters allow an optimal fit for standard tubes, lysis tubes, microplates, glass vials and other sample vessels. An excellent temperature uniformity and homogeneity is guaranteed for all samples.

COMFORT

Simple intuitive integration in robots and programming

The BioShake can be operated via RS232 or USB user interface. An automatic initialization will start after turn on.

A simple command set allows you to easily control hardware and sensors. The process parameters are constantly controlled and read out. A self-setting zero position of the shaker plate after turning off makes the timeconsuming electrical tracking unnecessary. This ensures a maximum of operating security also in the unmonitored continuous operation.

QInstruments provides approved SILA® drivers for all BioShake units.

UNIQUE DESIGN MEETS HIGH-END TECHNOLOGY

First-class finished aluminium housing

Unique and efficient design combined with the most compact housing result in beautiful and well-defined laboratory equipment. Therefore, the first-class finished aluminium housing gives the BioShake 3000-T its essential functionality. It provides a high amount of security, device stability and ensures a long service life.

Safety of the user and ease of use are clearly a priority.

MADE IN GERMANY

High-end instruments for daily routine

A perfectly harmonious blend of high-tech and handmade. "Made in Germany" has always been a recipe for success for QInstruments. 100% of QInstruments production takes place in Germany.

The focus is on human diligence and on being environmentally friendly. The company upholds its quality guarantee by means of consistent quality management. For more than 15 years these lab automation professionals from Jena have used only high-quality materials to ensure sustainable production, applied innovative thinking and undertaken research in a future-oriented way – all as a matter of course.

Recommended mixing speeds

The adjustment of the optimal mixing frequency in depending on filling volume per well should always be made in dependence on the size of the well and the filling volume.

Only in this way optimum results can be achieved with in shortest process time with a high reproducibility.

MICROPLATES

Recommended mixing speeds

* Values for 96 - 384 well plates refer to diluted fluids and mixing orbit of 2.0 mm.

** Values for 1536 well plates refer to mixing orbit of 1.2 mm.

| Filling volume in % | 96 well plates* | 384 well plates* | 384 well plates* | 1536 well plates** |

|---|---|---|---|---|

10 % | 1800 - 2200 rpm | 2200 - 2600 rpm | 2800 - 3000 rpm | 4000 - 5000 rpm |

25 % | 1600 - 2000 rpm | 2000 - 2400 rpm | 2400 - 3000 rpm | 3500 - 4500 rpm |

50 % | 1400 - 1800 rpm | 1800 - 2200 rpm | 2200 - 2600 rpm | 2800 - 3500 rpm |

75 % | 1200 - 1600 rpm | 1600 - 2000 rpm | 2000 - 2400 rpm | 2500 - 3000 rpm |

TUBES

Recommended mixing speeds

All values refer to diluted fluids and mixing orbit of 2.0 mm.

| Filling volume in % | 0.2 ml tubes | 0.5 ml tubes | 1.5 ml tubes | 2.0 ml tubes |

|---|---|---|---|---|

10-50 % | 1400 - 1800 rpm | 1200 - 1600 rpm | 1000 - 1300 rpm | 1000 - 1300 rpm |

50-75 % | 1200 - 1500 rpm | 1100 - 1300 rpm | 1000 - 1200 rpm | 900 - 1200 rpm |

75-90 % | 1000 - 1300 rpm | 1000 - 1200 rpm | 900 - 1100 rpm | 900 - 1100 rpm |

GLASS VIALS

Recommended mixing speeds

All values refer to diluted fluids and mixing orbit of 2.0 mm.

| Filling volume in % | 0.5 ml vials | 2.0 ml vials | 4.0 ml vials | 6.0 ml vials |

|---|---|---|---|---|

10-50 % | 1400 - 1800 rpm | 1200 - 1600 rpm | 1000 - 1300 rpm | 1000 - 1300 rpm |

50-75 % | 1200 - 1500 rpm | 1100 - 1300 rpm | 1000 - 1200 rpm | 900 - 1200 rpm |

75-90 % | 1000 - 1300 rpm | 1000 - 1200 rpm | 900 - 1100 rpm | 900 - 1100 rpm |

For vials & tubes use only | |

|---|---|

| Glass vials | 2.0, 4.0, up to 6.0 ml glass vials |

Tubes | 0.2 / 0.5 / 1.5 / 2.0 ml standard microcentrifuge tubes |

Mixing | |

| Mixing frequency | 200 to 3,000 rpm (microplates) |

| Mixing orbit | constant 2.0 mm diameter |

| Speed setting resolution | linear increments |

| Mixing regulation accuracy | ± 25 rpm |

| Zero position | Automatically controlled in the stopping process with final fixing Stopping time selectable from 3 sec (strong stopping) to 30 sec (soft stopping) |

| Zero position accuracy | ± 0.1 mm |

Temperature | |

| Temperature range | ambient to 99°C |

| Temperature setting | 0.5°C or 1°C increment (adjustable in the setup) adjustable from 0°C to 99°C |

| Temperature accuracy | ± 0.1°C |

Temperature uniformity | ± 0.5°C at 45°C ± 0.7°C at 75°C ± 1.0°C at 95°C |

| Heat-up time | ca. 7°C/min (from ambient to 95°C in 10 min) |

Device control | |

Electronic control board | Completely accommodated in the smallest housing |

Controller | Micro controller (16-Bit-RISC-Prozessor) |

Operation control | Remote controlled |

User interface | RS232 interface |

| Status & alarm | LED in front (green = ok, red = alarm) |

Electrical | |

| Operating Voltages | 24 VDC input . Imax: 3.1 A . Peff: 85 Watt . Pmax: 108 Watt |

| External power supply | External power supply unit (CE/UL/CSA approved, 85-264 VAC, 47-63 Hz, 120W, IEC/EN60320-1 C14) |

Properties | |

| Housing Material | Aluminum anodized |

| Environment operating range | +5°C to 45°C (80 % max. relative humidity) |

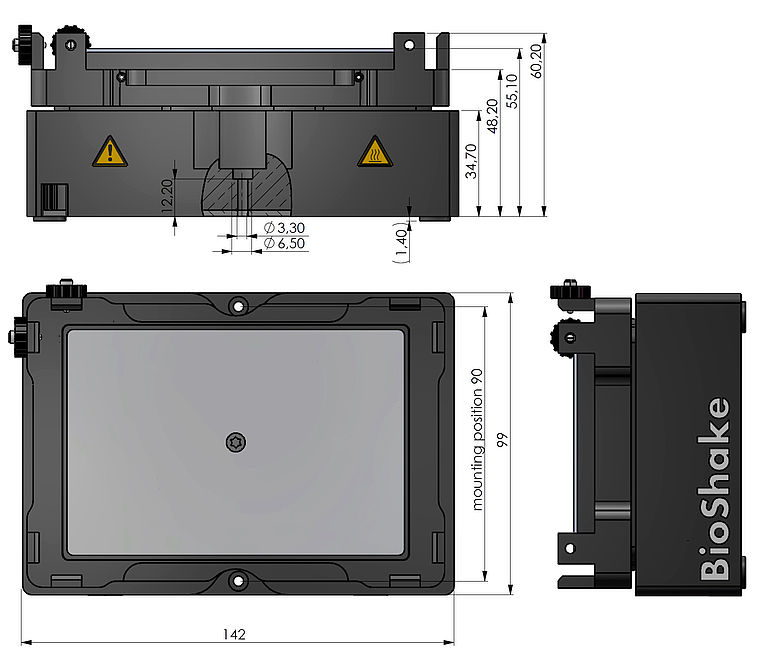

| Dimensions (W x D x H) | 142 mm x 99 mm x 61.6 mm |

| Weight | 1.5 kg (3.3 lbs) |

Dimensions

Here we present an overview of available standard adapters, compatible with all automation units:

BioShake 3000 | BioShake 3000-T | BioShake 3000-T elm | BioShake D30-T elm | BioShake Q1 | HeatPlate | ColdPlate

Microplates

Standard

2016-1021 | Microplate . Flat bottom standard

2016-1022 | Microplate . Flat bottom High Base

2016-1032 | Microplate . 96 well round bottom

PCR microplates

2016-1041 | PCR plate . Eppendorf® 96/150µl

2016-1042 | PCR plate . Bio-Rad® 96/150µl

2016-1051 | PCR plate . Eppendorf® 384/40µl

Deep well & storage plates

2016-1121 | Deep well . Eppendorf® 96/500-1000 µl

2016-1141 | Deep well . BRAND®/Trefflabs® 96/1.1 ml

2016-1151 | Deep well . NUNC®/Axygen® 96/2.0 ml

2016-1161 | Deep Well . Axygen® 96/0.6 ml

2016-1171 | Deep Well . Abgene® 96/2.2 ml

2016-1172 | Deep Well . Abgene®/HJ-Bio®/Greiner® 96/0.8-1.2 ml

2016-1181 | Deep Well . Sarstedt® 96/2.2 ml Megablock

2016-1201 | 96 well V bottom . Corning® 96/320 µl

2016-1214 | Deep well . Axygen®/Corning®/StarLab® 96/2.0 ml

2016-1215 | 24 well . Whatman® Uniplate

2016-1217 | Storage plate . NUNC® 96/450 µl

2016-1218 | Deep well . Apricot® 96/2.2 ml

Tubes & Stripes & Vials

Conical shape

2016-1060 | Tubes . 15x 5.0 ml

2016-1061 | Tubes . 24x 2.0 ml . 15x 0.5 ml

2016-1062 | Tubes . 24x 1.5 ml . 15x 0.5 ml

2016-1063 | Tubes . 40x 0.5 ml . 28x 0.2 ml

2016-1064 | PCR Tubes/Stripes/Plates . 96x 0.25 ml

2016-1093 | FALCON® tubes . 5x 50 ml

2016-1094 | FALCON® Tubes . 12x 15 ml

Cylindrical shape

2016-1069 | Vials . 35x 2.0 ml Ø 10.8 mm

2016-1071 | Vials . 35x 2.0 ml Ø 12 mm

2016-1080 | Vials . 35x 2.0 ml Ø 12.5 mm

2016-1078 | Vials . 24x 2.0 ml Ø 12.7 mm

2016-1081 | Vials . 30x 2.0 ml Ø 13 mm

2016-1072 | Vials . 24x 4.0 ml Ø 15 mm

2016-1073 | Vials . 20x 4.0 ml Ø 17 mm

2016-1074 | Vials . 20x 6.0 ml Ø 19 mm

Technical data sheet

Test software

QCOM 2 is a small test software with a graphical user interface (GUI) to control lab automation instruments from QInstruments, eg. BioShake, ColdPlate, HeatPlate. The main purpose of QCOM 2 is to get easy access to the unit to execute initial testing.

SILA 2 compliant driver

SiLA® is the global initiative to standardize software interfaces in the field of life science research instrumentation. Instigated by the pharmaceutical industry′s need for flexible laboratory automation, the initiative is supported by major device and software suppliers worldwide.

The SiLA® consortium for Standardization in Lab Automation develops and introduces new interface and data management standards allowing rapid integration of lab automation systems. SiLA is a not-for-profit membership corporation with a global footprint and is open to institutions, corporations and individuals active in the life science lab automation industry. Leading system manufacturers, software suppliers, system integrators and Pharma/Biotech corporations have joined the SiLA® consortium and contribute in different technical work groups with their highly skilled experts.

QInstruments provides approved SILA® driver 1 for all BioShake units.

For development of SILA compliant software we work in close cooperation with Equicon.

To obtain help for installing and running the driver, please contact us.

3D CAD models

Certificates / Declarations

Knowledge

Leveraging its foundation in innovative automated solutions, QINSTRUMENTS is a leader in precision mixing and temperature control for sample preparation. QINSTRUMENTS' application-specific solutions, small instruments and OEM modules are used in industries ranging from flow cytometry and forensic chemistry to next-generation sequencing.

QINSTRUMENTS offers extremely robust and quiet orbital shakers, thermoshakers, heating and cooling units for laboratory automation. The black colored premium line is designed for demanding automation processes and defines the global standard for reliable mixing.

No other external components are needed as the electronics are integrated into the smart modules. They are fully equipped for hands-free operation with a comprehensive remote command set for easy software integration.